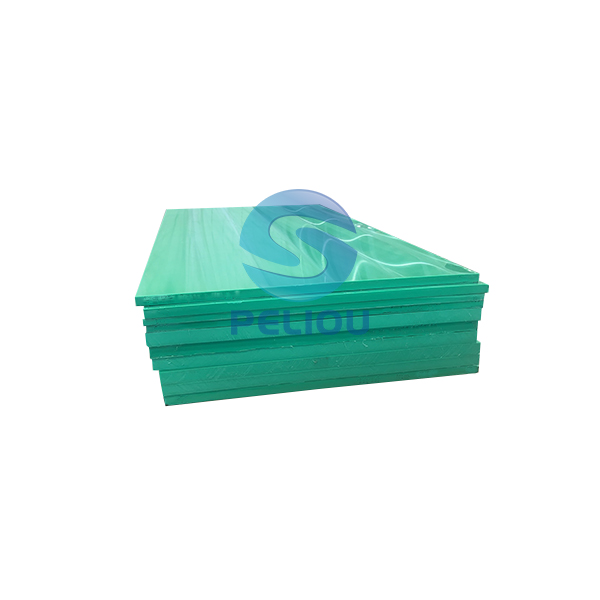

In today’s industrial world, choosing the right material is critical to the performance and economics of your equipment. UHMWPE (Ultra-high molecular weight polyethylene) sheet, with its unrivaled properties, is becoming the “secret weapon” of industry. But what makes UHMWPE sheet so special? Let us reveal its unique benefits and why it deserves to be the material of choice for your next project!

Top abrasion resistance

UHMWPE plastic sheet is known for its extremely low coefficient of friction and superior abrasion resistance. It is able to withstand harsh abrasive environments and is perfect for applications such as mining conveyor belts, construction equipment, and other applications that require high abrasion resistance. Choosing uhmw natural sheet can greatly extend equipment life and reduce maintenance costs!

High impact strength

UHMWPE sheet maintains excellent toughness even under extreme conditions. Its high impact strength ensures that it does not become brittle even at low temperatures. Suitable for a wide range of mechanical components and transportation equipment, it is able to withstand sudden impacts and protect your equipment.

Excellent chemical resistance

Facing the challenge of chemical corrosion, UHMWPE sheet stands out with its excellent chemical resistance. It is resistant to a wide range of acids, alkalis and solvents, and is widely used in chemical storage tanks and pipe linings to ensure safety and reliability and reduce maintenance frequency.

Low water absorption

UHMWPE sheet absorbs little water in wet environments, which allows it to perform consistently in wet conditions. Whether the application is water treatment or in a wet environment, UHMWPE sheet maintains its excellent physical properties.

Self-lubricating performance

The self-lubricating properties of UHMWPE sheet greatly reduce the need for external lubricants, reducing friction and wear. This characteristic makes it particularly important for use in sliding parts and bearings, improving equipment operating efficiency and reducing maintenance costs.

Lightweight and easy to process

Compared to many traditional materials, UHMWPE sheet is lighter and easier to process. Whether it’s cutting, drilling or welding, UHMWPE sheet can be easily adapted to a variety of customized needs, making it ideal for use in a wide range of industrial and manufacturing environments.

Widely used

From medical devices to food processing, from mining to transportation, UHMWPE sheet is used in a wide range of applications for its superior performance. Its versatility makes it the material of choice for solutions across a wide range of industries.

Conclusion

UHMWPE sheet is becoming the ultimate solution for industry due to its superior abrasion resistance, high impact strength, chemical resistance, low water absorption and self-lubricating properties. If you’re looking for a material that will enhance equipment performance, reduce maintenance costs, and provide long-lasting reliability, then UHMWPE sheet is definitely the material for you!

Want to learn more? Contact us today to explore how UHMWPE sheet can be used in your projects to bring about more efficient and long-lasting solutions!

uhmw sheets for sale UHMWPE Industrial Materials High Performance Wear Resistant Materials Innovative Solutions Engineering Plastics

Peliou

Peliou

HelloPlease log in